- Flooded suction required

- Number of Additives: 1 Standard, up to 4 optional

- 4" 150# connection standard (other connections available, consult factory for details)

- Injection Ratios: 0-4000 ppm depending upon application

- 75-700 gpm continuous operation

- Product Temperature Range: -40°F to +250°F (-40°C to +121°C)

- Maximum product line pressure: 150 psi. Higher pressures available with upgraded flanges installed

- Product Viscocities: up to 10,000 ssu

- Fuels, Oils, Additives and Liquid Gases

- Duty Cycle: Intermittent

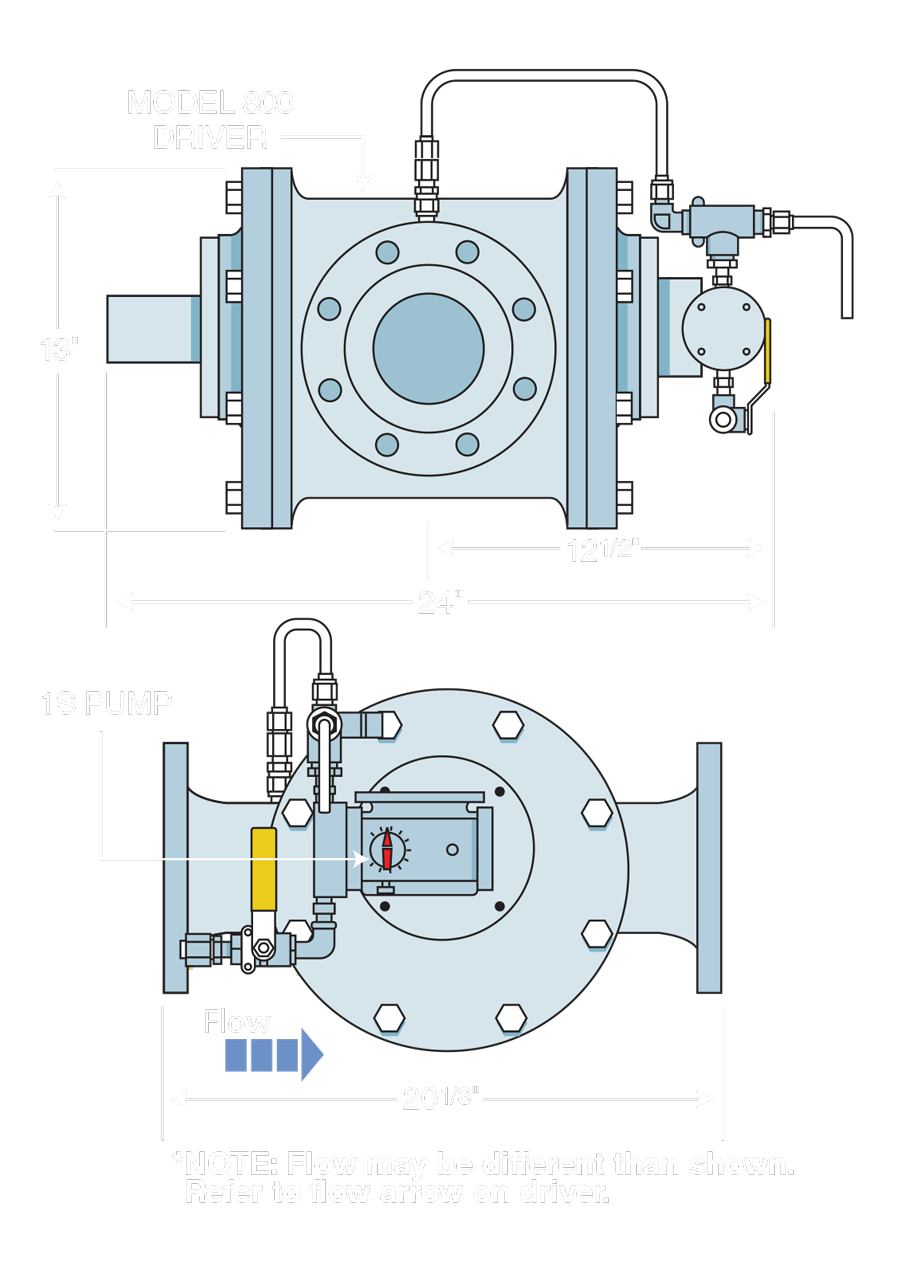

Model 800

Model 800

The 800 offers precision injection of additives meeting the requirements of delivery terminals, high-volume delivery vehicles and truck loading racks. Self contained and requires no product meters or pulsars.

- Simple, economical installation

- Guaranteed precision blending

- No power or meter required

- 4” 150# ANSI connections

- Passive, automatic operation

SPECIFICATIONS

CONSTRUCTION MATERIALS

- Aluminum casting; carbon steel fabrication optional

- Metering Pump: All wetted parts 300 series stainless steel

- Elastomers: Aflas, Viton, and Teflon; other elastomers available upon request

- Mechanical Seal: Carbon on Ceramic, optional Tungsten on Carbon

- Upgrade to Hammonds "Smart" System

Trusted by Industry Leaders Worldwide

For over three decades, Hammonds has been the global standard in additive injection technology, delivering innovative solutions that protect fuel systems across every continent.

0+

Systems Installed

0+

Countries Worldwide

0+

Years of Excellence